HY Polyurethane cable tray

HUAYU

| Availability: | |

|---|---|

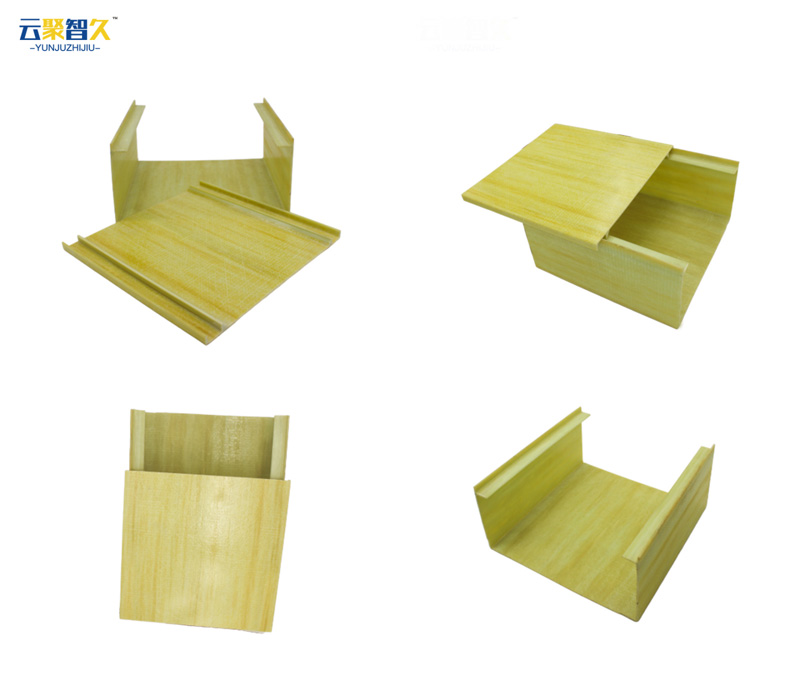

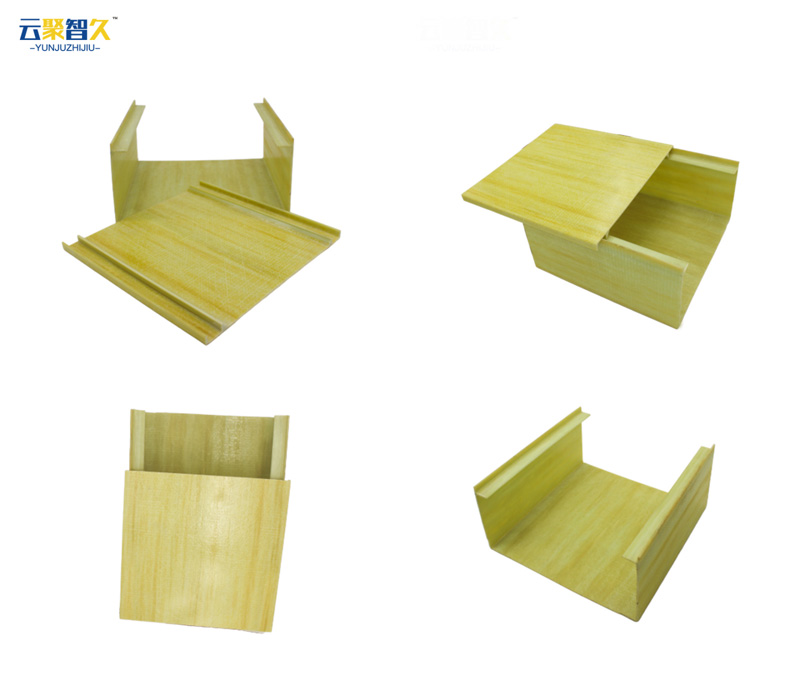

The Polyurethane cable tray represents a versatile and durable solution for managing and organizing cables in various industrial and commercial settings. Engineered with precision, these trays are crafted from high-quality polyurethane materials, renowned for their exceptional strength, flexibility, and resistance to corrosion and environmental degradation.

The Polyurethane cable tray represents a versatile and durable solution for managing and organizing cables in various industrial and commercial settings. Engineered with precision, these trays are crafted from high-quality polyurethane materials, renowned for their exceptional strength, flexibility, and resistance to corrosion and environmental degradation.

Advantage:

1.Designed to accommodate a wide range of cable types and sizes

2.Polyurethane cable trays offer superior cable support and protection while ensuring ease of installation and maintenance.

3.Their lightweight construction and modular design make them ideal for use in diverse applications such as telecommunications, power distribution, data centers, and industrial facilities.

4.With their ability to withstand harsh operating conditions and provide reliable cable management solutions, Polyurethane cable trays stand as a reliable choice for enhancing safety, efficiency, and organization within electrical systems.

Raw materials | Polyurethane composite | Unsaturated polyester resin composite material | 063-T5aluminium alloy profile | 45#steel |

Density/g·cm3 | 2.1 | 2.0 | 2.7 | 7.9 |

Tensile strength/MPa | 1290 | 610 | 145 | 600 |

Tensile modulus/GPa | 52 | -- | 68.9 | 200 |

| Property | Polyurethane composite | aluminium alloy | PVC | Nylon insulation strip | Polyurethane FRP |

Density/g·cm3 | 2.1 | 2.79 | 1.5 | 2.7 | 2.0 |

Thermal conductivityW·(m·K)-1 | 0.22 | 160 | 0.35 | 0.30 | 0.40 |

Bending strength/MPa | 1700 | 250 | 30 | 80-180 | 300-400 |

Bending modulus/ GPa | 41 | 50-80 | 2.2-5 | 2-5 | 10-22 |

Linear coefficient expansion/10-6·℃-1 | 5-8 | 22-24 | 50-85 | 24-35 | 7.3 |

Product advantages

Telecommunications: Polyurethane Cable Trays are widely used in telecommunications networks to organize and support cables for voice, data, and video transmission. They help maintain cable integrity and prevent signal interference, ensuring reliable communication systems.

Power Distribution: In electrical power distribution systems, Polyurethane Cable Trays play a crucial role in organizing and supporting power cables, including high-voltage lines, distribution cables, and wiring harnesses. They facilitate efficient power transmission and reduce the risk of cable damage or electrical hazards.

Data Centers: Polyurethane Cable Trays are essential components in data center infrastructure, where they support and organize a vast network of cables for servers, switches, routers, and other networking equipment. Their modular design and cable management capabilities contribute to efficient airflow, cooling, and maintenance within data center environments.

Industrial Facilities: In industrial settings such as manufacturing plants, refineries, and processing facilities, Polyurethane Cable Trays provide robust cable management solutions for machinery, equipment, and instrumentation. They help streamline operations, minimize downtime, and ensure safety compliance by preventing cable tangling, abrasion, and electrical faults.

Commercial Buildings: Polyurethane Cable Trays are commonly used in commercial buildings, including office complexes, retail centers, hospitals, and educational institutions, to organize and route electrical and communication cables discreetly and efficiently. They contribute to the overall aesthetics and functionality of building infrastructure while ensuring reliable connectivity and safety.

Transportation Infrastructure: Polyurethane Cable Trays find applications in transportation infrastructure projects such as airports, railways, and tunnels, where they provide secure cable routing and protection in challenging environments. They withstand vibrations, temperature fluctuations, and exposure to moisture, maintaining uninterrupted communication and signaling systems.

In summary, the application of Polyurethane Cable Trays encompasses a wide range of industries and environments, where they serve as essential components for efficient and reliable cable management, contributing to operational efficiency, safety, and connectivity.

Advantage:

1.Designed to accommodate a wide range of cable types and sizes

2.Polyurethane cable trays offer superior cable support and protection while ensuring ease of installation and maintenance.

3.Their lightweight construction and modular design make them ideal for use in diverse applications such as telecommunications, power distribution, data centers, and industrial facilities.

4.With their ability to withstand harsh operating conditions and provide reliable cable management solutions, Polyurethane cable trays stand as a reliable choice for enhancing safety, efficiency, and organization within electrical systems.

Raw materials | Polyurethane composite | Unsaturated polyester resin composite material | 063-T5aluminium alloy profile | 45#steel |

Density/g·cm3 | 2.1 | 2.0 | 2.7 | 7.9 |

Tensile strength/MPa | 1290 | 610 | 145 | 600 |

Tensile modulus/GPa | 52 | -- | 68.9 | 200 |

| Property | Polyurethane composite | aluminium alloy | PVC | Nylon insulation strip | Polyurethane FRP |

Density/g·cm3 | 2.1 | 2.79 | 1.5 | 2.7 | 2.0 |

Thermal conductivityW·(m·K)-1 | 0.22 | 160 | 0.35 | 0.30 | 0.40 |

Bending strength/MPa | 1700 | 250 | 30 | 80-180 | 300-400 |

Bending modulus/ GPa | 41 | 50-80 | 2.2-5 | 2-5 | 10-22 |

Linear coefficient expansion/10-6·℃-1 | 5-8 | 22-24 | 50-85 | 24-35 | 7.3 |

Product advantages

Telecommunications: Polyurethane Cable Trays are widely used in telecommunications networks to organize and support cables for voice, data, and video transmission. They help maintain cable integrity and prevent signal interference, ensuring reliable communication systems.

Power Distribution: In electrical power distribution systems, Polyurethane Cable Trays play a crucial role in organizing and supporting power cables, including high-voltage lines, distribution cables, and wiring harnesses. They facilitate efficient power transmission and reduce the risk of cable damage or electrical hazards.

Data Centers: Polyurethane Cable Trays are essential components in data center infrastructure, where they support and organize a vast network of cables for servers, switches, routers, and other networking equipment. Their modular design and cable management capabilities contribute to efficient airflow, cooling, and maintenance within data center environments.

Industrial Facilities: In industrial settings such as manufacturing plants, refineries, and processing facilities, Polyurethane Cable Trays provide robust cable management solutions for machinery, equipment, and instrumentation. They help streamline operations, minimize downtime, and ensure safety compliance by preventing cable tangling, abrasion, and electrical faults.

Commercial Buildings: Polyurethane Cable Trays are commonly used in commercial buildings, including office complexes, retail centers, hospitals, and educational institutions, to organize and route electrical and communication cables discreetly and efficiently. They contribute to the overall aesthetics and functionality of building infrastructure while ensuring reliable connectivity and safety.

Transportation Infrastructure: Polyurethane Cable Trays find applications in transportation infrastructure projects such as airports, railways, and tunnels, where they provide secure cable routing and protection in challenging environments. They withstand vibrations, temperature fluctuations, and exposure to moisture, maintaining uninterrupted communication and signaling systems.

In summary, the application of Polyurethane Cable Trays encompasses a wide range of industries and environments, where they serve as essential components for efficient and reliable cable management, contributing to operational efficiency, safety, and connectivity.

Application:

Subway Tunnels

Bridge Pipelines

Highways

Ports

Airports

Application:

Subway Tunnels

Bridge Pipelines

Highways

Ports

Airports